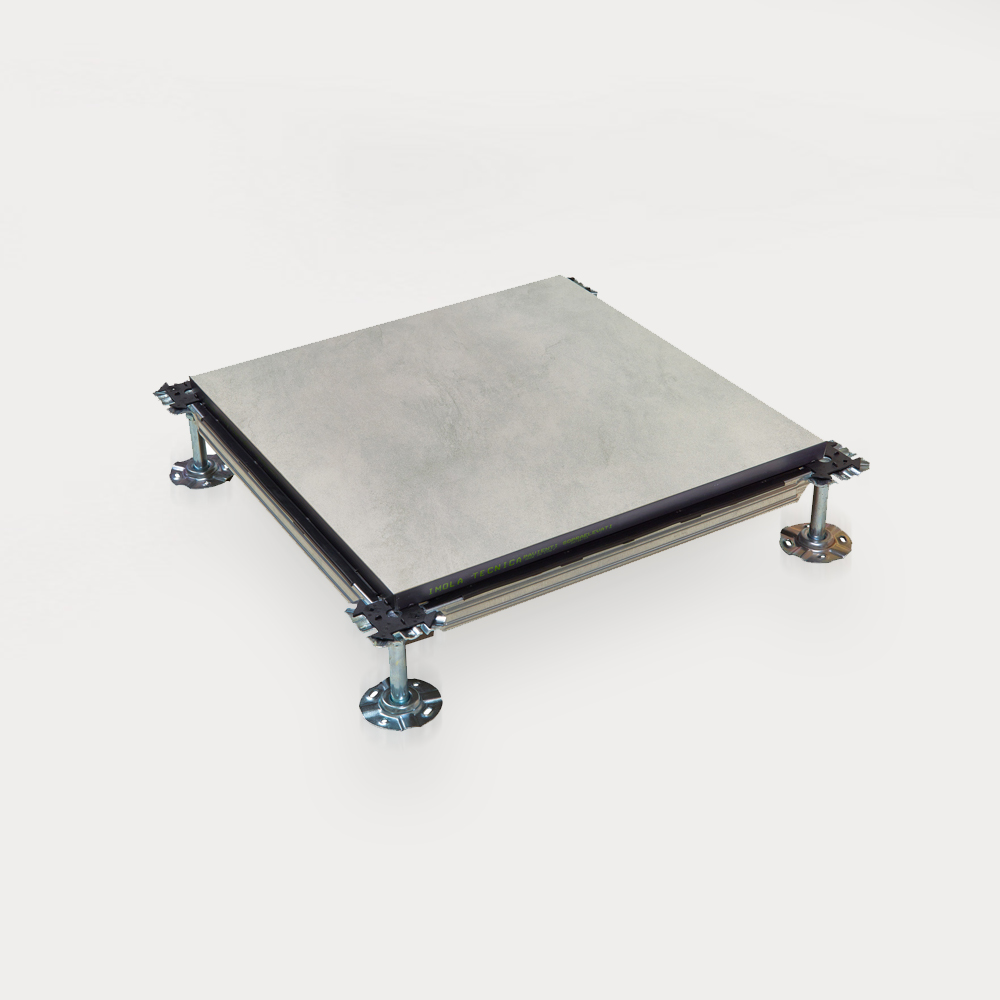

Support column base

Base: Round with a diameter of 93 mm, 1.5 mm thick, reinforced with ribbing to increase structural rigidity and complete with slots for securing it to the slab.

The base is shaped so a pipe measuring 20×2 mm and with a variable height can be fitted into it and pressure-fixed at the base by means of the particular nature of the pipe itself.

Head: cold-moulded square measuring 80×80 mm, 2.5 mm thick and including a slot for fitting the head gasket.

Adjustment system: at the centre of the head, a nut and bolt unit is included with a micrometric anti-loosening mechanism that enables the height of the entire structure to be adjusted until the correct final position is reached.