A building with an effective ventilated façade considerably improves its energy consumption and reduces the emission of waste: in particular, the ventilated façade project reduces energy consumption from 30% to 70%, water from 30 to 50% and waste from 50% to 90%. Lastly, it can reduce carbon dioxide emissions (the harmful emission of greenhouse gas) into the atmosphere by 35%.

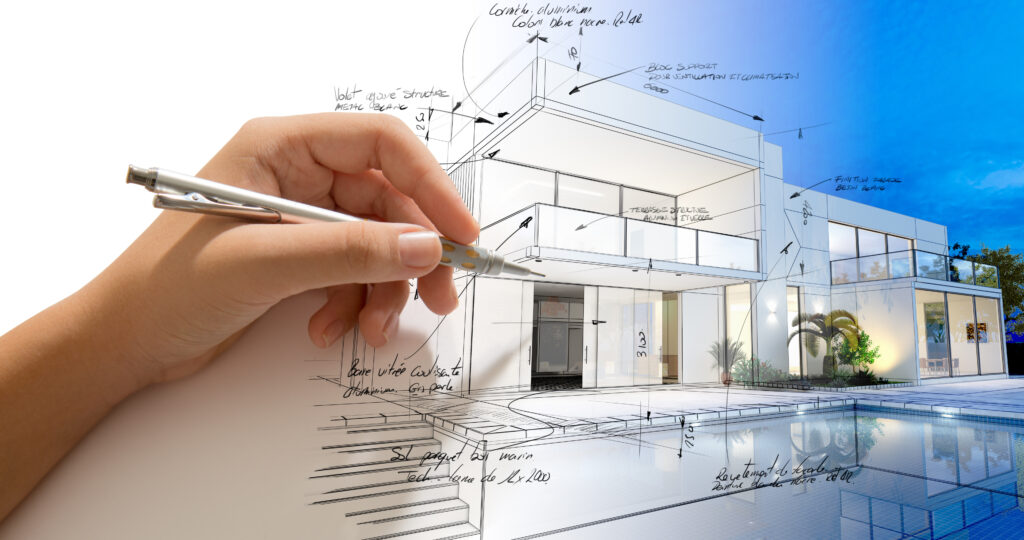

An effective ventilated façade design – regarded as the most effective system for insulating a building, and as a result, has gradually gained increasingly greater consent among architects and builders because it eliminates unwanted thermal bridges as well as problems of condensation, resulting in an excellent thermo-hygrometric performance from the building – should bear in mind at least five criteria of the ventilated façade design.

- The quality of the internal environment and innovation;

- Materials and resources used;

- Sustainability;

- Efficient use of water;

- Energy and energetic impact.

It is extremely interesting to note how the trends and personal tastes expressed through the colour in interior design are increasingly moving towards the outside, where there is a large number of requests for colours and trimmings on buildings. Colours and trimmings whose purpose is to emanate life and individuality as well as personality. And from this point of view, the ventilated façade design criteria offer endless creative opportunities. Right now, it is easy to play around with ventilated façades: in particular, the porcelain stoneware slabs are the best solution for cladding a ventilated façade because they are lighter than stone materials, such as stone or marble, are more resistant and easier to maintain and clean. In addition to this, from a visual point of view, the porcelain stoneware offers you the chance to custom design your architectural project tout court, thanks to a vast range of colours, different types of texture – wood effect finishings, marble, stone and terracotta-cement – and the extensive range of shapes on offer.

Ventilated façade design criteria: an ad hoc system for any situation.

During the ventilated façade design process, it is essential to bear in mind the size of the external façade element and create the façade project keeping in mind both the opaque panels and holes in the façade, in order to rationalise the use of the slabs, avoiding waste and unnecessary cuts.

When establishing the overall thickness of the façade, the fact that the overall thickness may vary depending on the air chamber selected, should be taken into consideration.

Depending on the kind of ventilated façade design and the arrangement of the external element designed, you can choose between one façade system or another. The movement joints or structural joints of a building always need to be respected, making the sub-structure and plate separate on both sides.

In more detail, the ventilated façade design done by Imola Tecnica involves technical staff drawing up the working architectural and structural design from an autocad format design (.dwg) provided by the client. A study is then carried out on all façades needing clad (again from a design supplied by the customer in .dwg format: drawings, frontages and sections), developed from a rational modification of the façades, with sizing of the modules relative to the parameter selected, architectural definition of window intrados, lower and upper façade closure and link solution for all the corners. The ventilated façade design rounds off, therefore, with a developed work and a technical description of the project with a layout of the structure, façade per façade, from where the positioning of all its components will be shown (rods with relative “fixed points” and “sliding points” profiles, etc.) with the Abacus of the slabs – with a definition of all the work to be carried out on them – and with the static verification report of the façade system in line with current standards on ventilated façades.

Ventilated façade fitting: the step by step process:

The fitting stages in the ventilated façade system follow a clearly set order. In more detail, the fitting system of the structure is carried out by arranging the elements in the following sequence:

- Ventilated façade fitting stages in the single and double framework structures: anchorage of the rods to the support structure and laying of an insulation layer, securing the insulation layer with suitable anchors, check and sealing of any exposed gaps when laying the insulation to avoid thermal bridges, arrangement of vertical struts on the rods, check the coplanarity with regard to the floor as well as between floors and securing the struts using screws or rivets;

- Ventilated façade fitting systems in the double framework: arrangement of horizontal tracks and the securing of screws or rivets to the vertical struts.

Imola Tecnica guarantees that the ventilated façade fitting is done by a highly qualified team: guaranteed assurance of good, practical work that will last over time.